I-API Iziqwenga Ezintathu zeCarbon Steel Flanged Motorized trunnion ball valve China Factory

Yintoni ivalvu yebhola ye-trunnion eneMotorized?

AIvalvu yebhola ye-trunnion eneenjinikuthetha ukuba ibhola ithintelwe ziibheringi kwaye ivunyelwe ukujikeleza kuphela, uninzi lomthwalo we-hydraulic luxhaswa ziingxaki zeNkqubo, nto leyo ebangela uxinzelelo oluphantsi lweebheringi kwaye kungabikho kudinwa kwe-shaft.

Uxinzelelo lombhobho luqhuba isihlalo esingaphezulu komsinga nxamnye nebhola engashukumiyo ukuze uxinzelelo lomgca lunyanzele isihlalo esingaphezulu komsinga ukuba siye ebholeni nto leyo ebangela ukuba sivale. Ukubambelela kwebhola ngoomatshini kutsala ukutyhalwa koxinzelelo lomgca, kuthintela ukungqubana okugqithisileyo phakathi kwebhola nezihlalo, ngoko ke nokuba kuxinzelelo olupheleleyo lokusebenza olunereyithingi epheleleyo, i-torque yokusebenza ihlala iphantsi. Oku kuluncedo ngakumbi xa ivalvu yebhola iqhutywa kuba inciphisa ubungakanani be-actuator kwaye ke ngoko iindleko zizonke zephakheji ye-valve actuation.

Iingenelo zoyilo lwebhola ye-trunnion kukuba i-torque yokusebenza iphantsi, kulula ukuyisebenzisa, ukunxitywa kwesihlalo okuncinci (Ukwahlulwa kwe-Stem/ball kuthintela ukulayisha ecaleni kunye nokunxitywa kwezihlalo ezisezantsi komlambo kuphucula ukusebenza kunye nobomi benkonzo), ukusebenza okuphezulu kokutywina kuxinzelelo oluphezulu noluphantsi (indlela eyahlukileyo yentwasahlobo kunye noxinzelelo lomgca ongaphezulu komlambo isetyenziswa njengesitywino nxamnye nebhola emileyo yokusetyenziswa koxinzelelo oluphantsi kunye noxinzelelo oluphezulu).

Iimpawu eziphambili ze-NORTECH Motorized trunnion ball valve

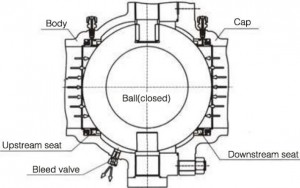

1. Ukuvimba kabini kunye nokopha (DBB)

Xa ivalvu ivaliwe kwaye umngxuma ophakathi uthululwe ngevalvu yokukhupha amanzi, izihlalo ezisezantsi neziphezulu ziya kuvala ngokwazo. Omnye umsebenzi wesixhobo sokukhupha amanzi kukuba isihlalo sevalvu sinokujongwa ukuba kukho ukuvuza ngexesha lovavanyo.

11. Isiqu soBungqina bokuqhushumba

Isiqu samkela isakhiwo esingavumeli ukutsha. Isiqu senziwe ngonyawo olusezantsi ukuze xa sibekwe isiciko sangaphezulu kunye nesikrufu, isiqu singavuthelwa yi-medium nokuba kukho ukunyuka okungaqhelekanga koxinzelelo kwivalvu.

Isiqu Esingqina Ukuqhushumba

2. I-Torque eSebenzayo ephantsi

Ivalvu yebhola yombhobho we-trunnion isebenzisa isakhiwo sebhola ye-trunnion kunye nesihlalo sevalvu esintantayo, ukuze ifikelele kwi-torque ephantsi phantsi koxinzelelo olusebenzayo. Isebenzisa i-PTFE ezithambisayo kunye ne-bearing yesinyithi etyibilikayo ukunciphisa i-friction coefficient iye kweyona iphantsi kunye nobunzulu obuphezulu kunye nesiqu esinobunono obuphezulu.

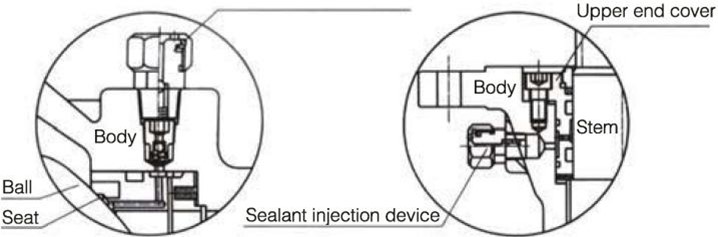

3. Isixhobo sokutywina esingxamisekileyo

Iivalvu zebhola ezinobubanzi obungaphezulu okanye obulingana ne-6' (DN150) zonke zenziwe ngesixhobo sokujova i-sealant kwisiqu nakwisihlalo. Xa iringi yesihlalo okanye iringi yesiqu O yonakele ngenxa yengozi, isitywini esifanelekileyo sinokujovwa sisixhobo sokujova i-sealant ukuze kuthintelwe ukuvuza okuphakathi kwiringi yesihlalo nakwisiqu.

13. Isiqu solwandiso

Ngokuphathelele ivalvu efakwe ngaphakathi, isiqu solwandiso sinokubonelelwa ukuba kufuneka kusetyenziswe umhlaba. Isiqu solwandiso senziwe ngesiqu, ivalvu yokutshiza i-sealant, kunye nevalvu yokukhupha amanzi enokwandiswa iye phezulu ukuze kube lula ukuyisebenzisa. Abasebenzisi kufuneka babonise iimfuno kunye nobude besiqu solwandiso xa bebeka ii-odolo. Kwivalvu yebhola eqhutywa nge-electric, pneumatic kunye ne-pneumatic - hydraulic actuators, ubude besiqu solwandiso kufuneka bube ukusuka embindini wepayipi ukuya kwi-flange ephezulu.

Umzobo wesicwangciso sesiqu solwandiso

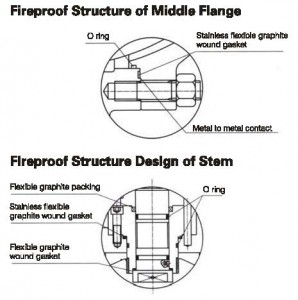

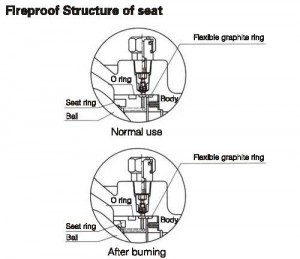

4. Uyilo lweSakhiwo esingatshiyo

Xa kutsha ngexesha lokusetyenziswa kwevalvu, iringi yesihlalo, iringi yesiqu se-O kunye neringi yeflange ephakathi ye-O eyenziwe nge-PTFE, irabha yezinye izinto ezingezizo ezesinyithi iya kubola okanye yonakale phantsi kobushushu obuphezulu. Phantsi koxinzelelo lwesixhobo, ivalvu yebhola iya kutyhala i-seat retainer ngokukhawuleza iye ebholeni ukuze yenze iringi yentsimbi iqhagamshelane nebhola kwaye yenze isakhiwo sokuncedisa ukutywina isinyithi ukuya kwisinyithi, esinokulawula ngokufanelekileyo ukuvuza kwevalvu.

5. Ulwakhiwo oluchasene nokuqina

Ivalvu yebhola yenzelwe isakhiwo esingashukumiyo kwaye isebenzisa isixhobo sokukhupha umbane ongashukumiyo ukwenza ngokuthe ngqo umjelo ongashukumiyo phakathi kwebhola nomzimba ngesiqu, ukuze ikhuphe umbane ongashukumiyo oveliswa kukungqubana ngexesha lokuvulwa nokuvalwa kwebhola kunye nesihlalo ngepayipi, ukuthintela umlilo wokuqhuma onokuthi ubangelwe yintlantsi engashukumiyo kunye nokuqinisekisa ukhuseleko lwenkqubo.

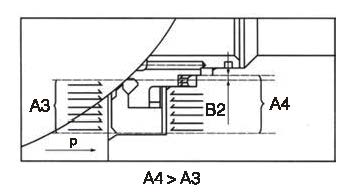

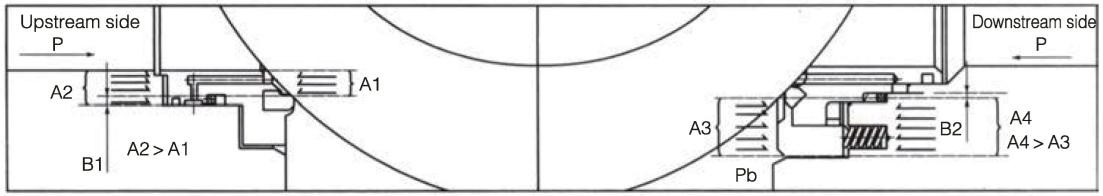

Icala elisezantsi: Nje ukuba uxinzelelo "Pb" ngaphakathi kwevalvu Cavity lunyuke, amandla asetyenziswa kwi-A3 aphezulu kunalawo akwi-A4. Njengoko i-A3-A4=B2, umahluko woxinzelelo kwi-B2 uya koyisa amandla entwasahlobo ukuze isihlalo sikhululwe ebholeni kwaye siphumeze uxinzelelo lwe-valve cavity ukuya kwindawo esezantsi emva koko, isihlalo kunye nebhola ziya kuvalwa kwakhona phantsi kwentshukumo yentwasahlobo.

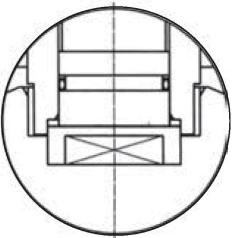

8. Ukutywina kabini (i-piston kabini)

Ivalvu yebhola yombhobho we-trunnion ingayilwa ngesakhiwo sokutywina kabini ngaphambi nasemva kwebhola kwiimeko ezithile zenkonzo ekhethekileyo kunye neemfuno zomsebenzisi. Inesiphumo sepiston kabini. Kwimeko eqhelekileyo, ivalvu ngokubanzi isebenzisa ukutywina okuphambili. Xa isihlalo esiphambili sitywina sonakele kwaye sibangela ukuvuza, isihlalo sesibini sinokudlala umsebenzi wokutywina kwaye siphucule ukuthembeka kokutywina. Isihlalo sisebenzisa isakhiwo esidibeneyo. Itywina eliphambili litywina lesinyithi ukuya kwisinyithi. Itywina lesibini yiringi yerabha ye-fluorine O enokuqinisekisa ukuba ivalvu yebhola inokufikelela kwinqanaba lokutywina le-bubble. Xa umahluko woxinzelelo uphantsi kakhulu, isihlalo sokutywina siya kucinezela ibhola ngentshukumo yasentwasahlobo ukuze kufezekiswe ukutywina okuphambili. Xa umahluko woxinzelelo uphakama, amandla okutywina esihlalo kunye nomzimba aya kwanda ngokufanelekileyo ukuze kutywinwe isihlalo kunye nebhola ngokuqinileyo kwaye kuqinisekiswe ukusebenza kakuhle kokutywina.

Ukuvalwa okuphambili: Phezulu.

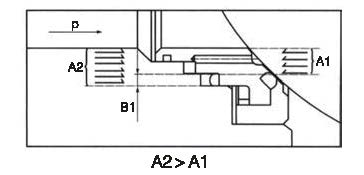

Xa umahluko woxinzelelo uphantsi okanye kungekho umahluko woxinzelelo, isihlalo esidadayo siya kuhamba nge-axial ecaleni kwevalvu phantsi kwentshukumo yentwasahlobo size sityhale isihlalo siye ebholeni ukuze sigcine ukutywinwa okuqinileyo. Xa isihlalo sevalvu siphezulu kunamandla asetyenziswa kwindawo A1,A2-A1=B1. Ke ngoko, amandla aku-B1 aya kutyhala isihlalo siye eBholeni aze enze ukutywinwa okuqinileyo kwenxalenye ephezulu.

9. Isixhobo soKhuseleko

Njengoko ivalvu yebhola yenzelwe ukutywinwa okuphambili kunye nokwesibini okunesiphumo sepiston ephindwe kabini, kwaye umngxuma ophakathi awukwazi ukwenza ukukhululeka koxinzelelo oluzenzekelayo, ivalvu yokunceda ukhuseleko kufuneka ifakwe emzimbeni ukuze kuthintelwe ingozi yomonakalo ongaphezulu koxinzelelo ngaphakathi komngxuma wevalvu onokwenzeka ngenxa yokwanda kobushushu be-medium. Uqhagamshelo lwevalvu yokunceda ukhuseleko ngokubanzi yi-NPT 1/2. Enye ingongoma ekufuneka iqatshelwe kukuba umngxuma wevalvu yokunceda ukhuseleko ukhutshelwa ngqo emoyeni. Kwimeko apho ukukhupha ngqo emoyeni akuvumelekanga, sicebisa ukuba ivalvu yebhola enesakhiwo esikhethekileyo sokukhulula uxinzelelo oluzenzekelayo ukuya kumsinga ophezulu kufuneka isetyenziswe. Jonga oku kulandelayo ukuze ufumane iinkcukacha. Nceda uyibonise ngokulandelelana ukuba awuyidingi ivalvu yokunceda ukhuseleko okanye ukuba ungathanda ukusebenzisa ivalvu yebhola enesakhiwo esikhethekileyo sokukhulula uxinzelelo oluzenzekelayo ukuya kumsinga ophezulu.

10. Ulwakhiwo oluKhethekileyo loNcedo oluZenzekelayo lokuNciphisa uxinzelelo oluya kuMsinga oPhezulu

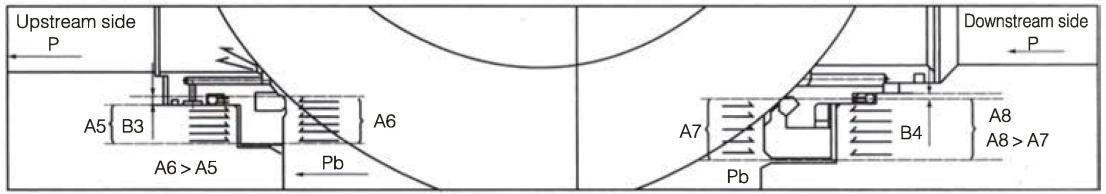

Njengoko ivalvu yebhola yenzelwe ukutywinwa okuphambili kunye nokwesibini okuphambili okunesiphumo sepiston ephindwe kabini, kwaye umngxuma ophakathi awukwazi ukukhulula uxinzelelo oluzenzekelayo, ivalvu yebhola kunye nesakhiwo esikhethekileyo iyacetyiswa ukuhlangabezana neemfuno zokunciphisa uxinzelelo oluzenzekelayo kwaye kuqinisekiswe ukuba akukho ngcoliseko kwindalo esingqongileyo. Kwisakhiwo, umjelo ophezulu usebenzisa ukutywinwa okuphambili kwaye umjelo osezantsi usebenzisa ukutywinwa okuphambili nokwesibini. Xa ivalvu yebhola ivaliwe, uxinzelelo kumngxuma wevalvu lunokwenza ukuncitshiswa koxinzelelo oluzenzekelayo kumjelo ongaphezulu, ukuze kuthintelwe ingozi ebangelwa luxinzelelo lomngxuma. Xa isihlalo esiphambili sonakele kwaye sivuza, isihlalo sesibini sinokudlala umsebenzi wokutywinwa. Kodwa ingqalelo ekhethekileyo kufuneka inikwe kwicala lokuhamba kwevalvu yebhola. Ngexesha lokufakelwa. Qaphela imiyalelo ephezulu nesezantsi. Jonga le mizobo ilandelayo yomgaqo wokutywinwa kwevalvu enesakhiwo esikhethekileyo.

Umzobo oyintloko wevalvu yebhola yokutywina phezulu nasezantsi

Umzobo osisiseko wokunciphisa uxinzelelo lwevalvu yebhola ukuya kumjelo ongasentla kunye nokutywinwa komjelo osezantsi

Iinkcukacha zevalvu yebhola ye-trunnion ye-NORTECH eneMotorized

Iinkcukacha zobugcisa zeTrunnion Ball Valve

| Ububanzi obuqhelekileyo | 2”-56”(DN50-DN1400) |

| Uhlobo loQhagamshelo | I-RF/BW/RTJ |

| Umgangatho woyilo | Ivalvu yebhola ye-API 6D/ASME B16.34/API608/MSS SP-72 |

| Izinto zomzimba | Intsimbi ephosiweyo/Intsimbi ephosiweyo/Intsimbi engatyiwayo/Intsimbi engatyiwayo ephosiweyo |

| Izinto zebhola | A105+ENP/F304/F316/F304L/F316L |

| Izinto zesihlalo | I-PTFE/PPL/INLON/I-PEEK |

| Ubushushu bokusebenza | Ukuya kuthi ga kwi-120°C kwi-PTFE |

|

| Ukuya kuthi ga kwi-250°C kwi-PPL/PEEK |

|

| Ukuya kuthi ga kwi-80°C kwi-NYLON |

| Isiphelo seFlange | I-ASME B16.5 RF/RTJ |

| Isiphelo se-BW | I-ASME B 16.25 |

| Ubuso ngobuso | I-ASME B 16.10 |

| Ubushushu boxinzelelo | I-ASME B 16.34 |

| Ikhuselekile emlilweni kwaye ayitshintshi mandla | I-API 607/API 6FA |

| Umgangatho wokuhlola | I-API598/EN12266/ISO5208 |

| Ubungqina bokuvela | I-ATEX |

| Uhlobo lomsebenzi | Ibhokisi yegiya yesandla/i-actuator ye-pneumatic/i-actuator yombane |

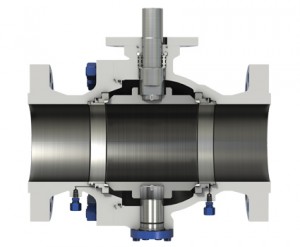

Umboniso weMveliso:

Ukusetyenziswa kweevalvu zebhola ezifakwe kwi-NORTECH Trunnion

Olu hloboI-Trunnion Enyuswe Ibhola yeValveIsetyenziswa kakhulu kwinkqubo yokusebenzisa, ukucokisa kunye nokuthutha ioyile, igesi kunye nezimbiwa. Ingasetyenziselwa ukuvelisa iimveliso zeekhemikhali, amayeza; inkqubo yemveliso yombane wamanzi, amandla obushushu kunye namandla enyukliya; inkqubo yokukhupha amanzi,