I-valve yebhola edadayo ye-ISO5211 yoMzi-mveliso oPhezulu oMgangatho oPhezulu Umthengisi wefektri waseTshayina Umenzi

Yintoni ivalvu yebhola edadayo?

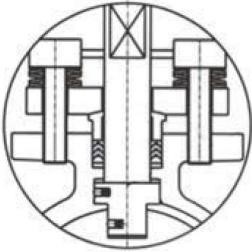

A ivalvu yebhola edadayoIvalvu enebhola yayo edadayo (engalungiswanga yi-trunnion) ngaphakathi komzimba wevalvu, iyahamba iye kwicala elisezantsi kwaye ityhale ngamandla kwisihlalo phantsi koxinzelelo oluphakathi ukuqinisekisa ukuthembeka kokutywina. Ivalvu yebhola edadayo inesakhiwo esilula, ukusebenza kakuhle kokutywina kodwa izixhobo zesihlalo ziyafuneka ukumelana nomsebenzi womthwalo kuba uxinzelelo lokutywina luvezwe yiringi yesihlalo. Ngenxa yokungafumaneki kwezinto zesihlalo ezisebenza kakuhle, ivalvu yebhola edadayo isetyenziswa kakhulu xa kusetyenziswa uxinzelelo oluphakathi okanye oluphantsi.

Xa ivalvu ibekwe apho imbobo ilungelelaniswe khona kwicala elifanayo nombhobho, ikwindawo evulekileyo, kwaye ulwelo lunokudlula ngezantsi. NORTECHIvalvu yebhola edadayo yimveliso entsha eyenziwe ngokuguqula ivalvu eqhelekileyo kunye nokwamkelwa komgangatho wamazwe ngamazwe ohlaziyiweyo.

Iimpawu eziphambili zevalvu yebhola edadayo ye-NORTECH ISO5211?

1. Uyilo lweSitulo esiKhethekileyo

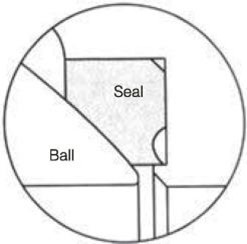

Sisebenzisa uyilo lwesakhiwo seringi yesitywina esiguquguqukayo sevalvu yebhola edadayo. Xa uxinzelelo oluphakathi luphantsi, indawo yoqhagamshelwano lweringi yesitywina kunye nebhola incinci. Iya kunciphisa ukungqubana kunye ne-torque yokusebenza kwaye iqinisekise ukuqina ngexesha elinye. Xa uxinzelelo oluphakathi lunyusiwe, indawo yoqhagamshelwano lweringi yesitywina kunye nebhola iba nkulu kunye nokuguquguquka kwe-elastic kweringi yesitywina, ukuze iringi yesitywina ikwazi ukumelana nempembelelo ephezulu ephakathi ngaphandle kokonakala.

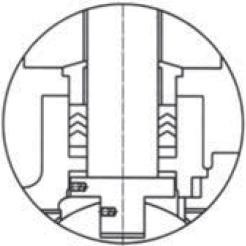

isihlalo esidadayo phantsi koxinzelelo oluphantsi

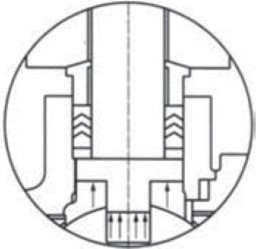

isihlalo esidadayo phantsi koxinzelelo oluphezulu

2. Uyilo lweSakhiwo esingatshiyo

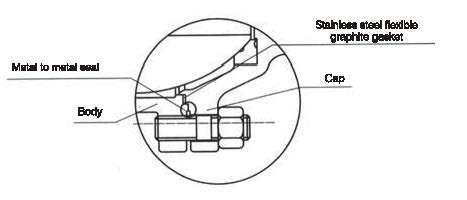

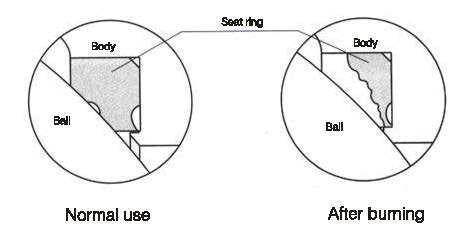

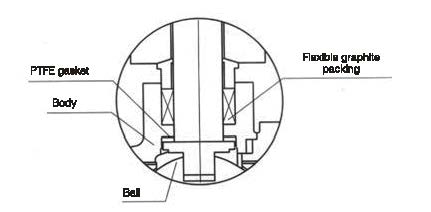

Kwimeko yomlilo ngexesha lokusetyenziswa kwevalvu, iringi yesihlalo eyenziwe nge-PTFE okanye ezinye izinto ezingezizo ezesinyithi iya kubola okanye yonakale phantsi kobushushu obuphezulu kwaye oko kuya kubangela ukuvuza okukhulu kolwelo, kuyingozi kakhulu kwindawo etshayo okanye eqhumayo. Iringi yesitywina engatshiyo ibekwe phakathi kwebhola nesihlalo ukuze emva kokuba isihlalo sevalvu sitshisiwe, le ndawo iya kuyityhala ibhola ngokukhawuleza iye kwiringi yesitywina yesinyithi esezantsi ukuze yenze isakhiwo sokuvala isinyithi ukuya kwisinyithi esinokulawula ngokufanelekileyo ukuvuza kwevalvu. Ukongeza, i-gasket yesitywina seflange ephakathi, enokuqinisekisa ukutywinwa nokuba kuphantsi kobushushu obuphezulu. Uyilo lwesakhiwo esingatshiyo sevalvu yebhola edadayo luhambelana neemfuno ze-APl607, APl6FA, BS 6755 kunye neminye imigangatho.

Ulwakhiwo olungatshiyo Uyilo lweflange ephakathi

Uyilo lweSakhiwo esingatshiyo soMthi (emva kokutshiswa)

Uyilo lweSitulo olungenamlilo

Uyilo lweSiqingatha Umlilo seStem (ukusetyenziswa okuqhelekileyo)

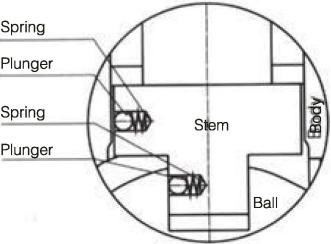

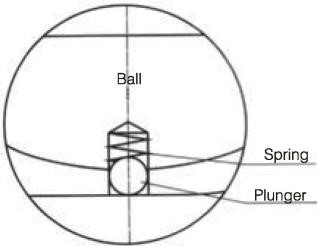

3. Ulwakhiwo oluchasene nokungashukumi

Ivalvu yebhola yenzelwe isakhiwo esichasene nokunganyakazi kunye nesixhobo sokukhupha umbane ongashukumiyo ukuze senze ngokuthe ngqo umjelo ongashukumiyo phakathi kwebhola nomzimba ngesiqu ukuze kukhutshwe umbane ongashukumiyo oveliswa kukungqubana kwebhola nesihlalo, kuthintelwe umlilo okanye ukuqhuma okunokubangelwa kukukhazimla okungashukumiyo kunye nokuqinisekisa ukhuseleko lwenkqubo.

Uyilo lwesakhiwo se-Anti-Static se-ball valve ene-DN32 nangaphezulu

Uyilo lwesakhiwo se-Anti-Static se-ball valve encinci kune-DN32

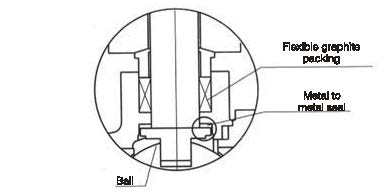

4. Ukutywinwa okuthembekileyo kweValve Stem

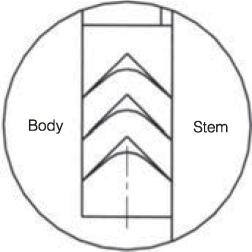

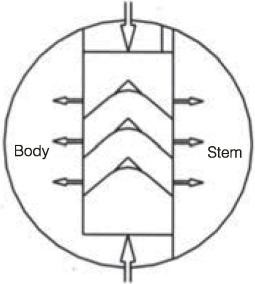

Ukongeza, ukuze kuthintelwe ukuvuza emva kokuba i-stem packing itshile xa kutsha, i-thrust bearing ibekwa kwindawo apho i-stem packing idibene khona nomzimba ukuze yenze i-reverse seal seal. Amandla okuvala e-reverse seal aya kwanda ngokwenyuka koxinzelelo oluphakathi, ukuqinisekisa ukutywinwa okuthembekileyo kwe-stem phantsi koxinzelelo olwahlukeneyo, ukuthintela ukuvuza kunye nokuthintela ukusasazeka kwengozi. Isakhiwo se-V packing seal senzelwe i-stem, i-V type packing inokutshintsha ngokufanelekileyo amandla okucindezela kunye namandla aphakathi e-gland ibe ngamandla okuvala e-stem. Ngokweemfuno zabasebenzisi, indlela yokucinezela i-disc spring packing elayishwe yi-disk spring ingasetyenziswa ukwenza ukutywinwa kwe-stem packing kuthembeke ngakumbi.

Isiqu esifakwe ezantsi asizukutshayiswa phantsi koxinzelelo oluphakathi

Isiqu esibekwe phezulu sinokuphuma xa uxinzelelo oluphakathi

Ngaphambi kokuba ukupakisha kucinezelwe

Emva kokuba ukupakisha kucinezelwe

indlela yokupakisha elayishwe entwasahlobo

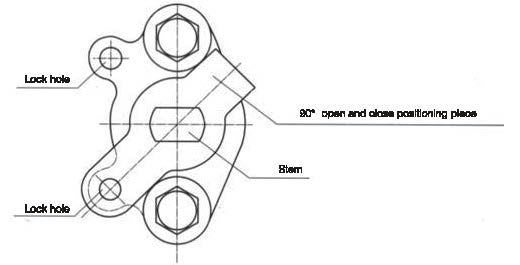

5. Ukuthintela ukutshixa kunye nokusetyenziswa gwenxa

Ivalvu yebhola yesandla ingatshixwa ngesitshixo kwindawo evulekileyo okanye evalekileyo ngokupheleleyo. Isixhobo sokubeka esivulekileyo nesivalekileyo esingama-90° esinomngxuma wokutshixa senzelwe ukuthintela ukusetyenziswa kakubi kwevalvu okubangelwa zii-opreators ezingagunyaziswanga, kwaye sinokuthintela nokuvulwa okanye ukuvalwa kwevalvu, okanye ezinye iingozi ezibangelwa kukungcangcazela kwepayipi okanye izinto ezingalindelekanga. Isebenza kakhulu ngakumbi kwi-oyile evuthayo neqhumayo, iikhemikhali kunye nemibhobho yokusebenza yezonyango okanye ityhubhu yasentsimini. Inxalenye esentloko yesiqu efakwe ngesiphatho isebenzisa uyilo oluthe tyaba.

Iinkcukacha zobugcisa zevalvu yebhola edadayo ye-ISO5211

| Ububanzi obuqhelekileyo | 1/2”-8”(DN15-DN200) |

| Uhlobo loQhagamshelo | Iflengi yobuso ephakanyisiweyo |

| Umgangatho woyilo | I-API 608 |

| Izinto zomzimba | Intsimbi engenasici CF8/CF8M/CF3/CF3M |

| Izinto zebhola | Intsimbi engenasici 304/316/304L/316L |

| Izinto zesihlalo | I-PTFE/PPL/INLON/I-PEEK |

| Ubushushu bokusebenza | Ukuya kuthi ga kwi-120°C kwi-PTFE |

|

| Ukuya kuthi ga kwi-250°C kwi-PPL/PEEK |

|

| Ukuya kuthi ga kwi-80°C kwi-NYLON |

| Isiphelo seFlange | EN1092-1 PN10/16,ASME B16.5 Cl150 |

| Ubuso ngobuso | I-ASME B 16.10 |

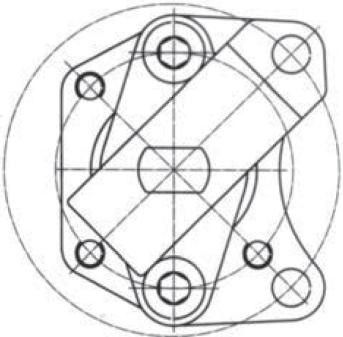

| Iphedi yokufakela ye-ISO | I-ISO5211 |

| Umgangatho wokuhlola | I-API598/EN12266/ISO5208 |

| Uhlobo lomsebenzi | Isixhobo sokuphatha/Ibhokisi yegiya yesandla/Isixhobo sokuqhuba umoya/Isixhobo sokuqhuba umbane |

Umboniso weMveliso: Ivalvu yebhola edadayo ye-ISO5211

Ukusetyenziswa kwevalvu yebhola edadayo ye-ISO5211

ZethuIvalvu yebhola edadayo ye-ISO5211ingasetyenziswa kakhulu kwi-petrochemical, chemical, intsimbi, iphepha, amayeza kunye neepayipi zothutho ezikude, phantse kulo lonke icandelo.